Easy Installation - Just measure, cut, glue, caulk, paint.

Measuring and Installation

StyroTrim stucco architectural accents are not only high quality, long-lasting, affordable stucco and cement-coated treatments, they are very easy to install.

Before placing an order, obtain the measurements of the wall, window or door areas where you intend to install the treatments.

All stucco StyroTrim sills, flat trims, deco trims and crown mouldings come in 85” length

strips, except for finished-end sills that can be ordered in custom lengths. You will use the strips in varying sizes and may need to cut them

down to specific widths. StyroTrim can be cut or mitered easily and fit

together to trim out most any opening. When placing your order, you need to indicate how

many 85” strips of each trim style you need for your project.

Window and Door Trim Measurements

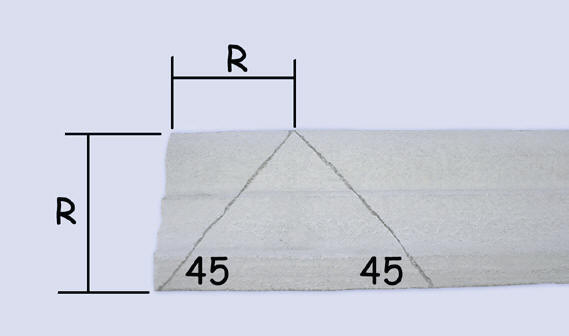

When

measuring windows and doors, be sure to account for the width of the trim on all

sides. Because the trim should be cut at 45 degrees at each corner, you should

measure to the outside finished corners for the trim. For "framed" windows, add

together both side heights and top and bottom widths to get the total

measurement. When

measuring windows and doors, be sure to account for the width of the trim on all

sides. Because the trim should be cut at 45 degrees at each corner, you should

measure to the outside finished corners for the trim. For "framed" windows, add

together both side heights and top and bottom widths to get the total

measurement.

For example, a four-foot wide by three-foot high window with 6"

trim on all

four sides measures:

2 x (48"

+ 6"

+ 6"

) + 2 x (36"

+ 6"

+ 6"

) = 216"

Divide 216"

by 85"

(piece length) = 2.54 pieces. This window needs three(3) 85"

length pieces of trim.

Window Sills

Suppose

your window has trim on the sides and the top, with a window sill at the

bottom. Since your window sill will typically extend beyond the trim (E) on each

side of the window you will need to compensate for these widths when ordering your

finished-end sill. The total sill length will be the width of the window, plus

two trim widths (W), plus the amount (E) you want to extend beyond the trim on

both sides. This will be your finished-end sill piece length. Suppose

your window has trim on the sides and the top, with a window sill at the

bottom. Since your window sill will typically extend beyond the trim (E) on each

side of the window you will need to compensate for these widths when ordering your

finished-end sill. The total sill length will be the width of the window, plus

two trim widths (W), plus the amount (E) you want to extend beyond the trim on

both sides. This will be your finished-end sill piece length.

For example, suppose your window is 60"

wide and you want your window sill to

extend 6"

beyond each side of the 6"

wide window trim. Add the window width

60"

+ ( 2 x 6"

trim widths)+ (2 x 6"

extensions each side) = 84"

of sill

needed. Simply specify an 84"

sill with finished ends when you order.

Cutting Window Sill Returns

If you purchased

stock sills with finished end returns,

please disregard these instructions.

If you purchase 85-inch

accent sills, please follow these

instructions to achieve a finished

return to your wall on each side of the

window.

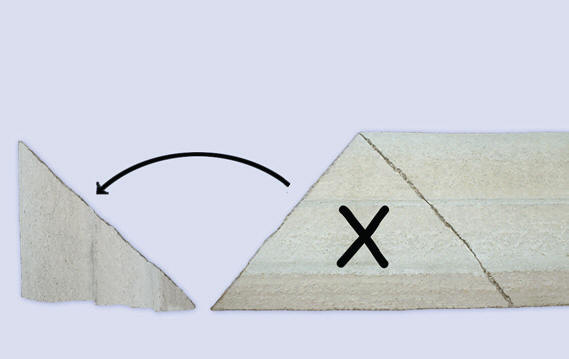

The cuts you make on

both ends of your sill for these returns

are why you must add extra lengths to

your sill measurements. Lay sill

flat-side down. At one end of your

sill, measure the return depth of the

flat side of the sill stick and mark it

on the sill face (d). At this

point, you will need to cut two miters

(an "upside down" V ) in the sill with

the point of the V at the place you

marked. Each cut must be 45

degrees as shown. By doing this,

you will cut two pieces from the sill.

|

The middle piece

that's a full triangle and mostly all

foam will be discarded and the one that

remains (with the most finished surface)

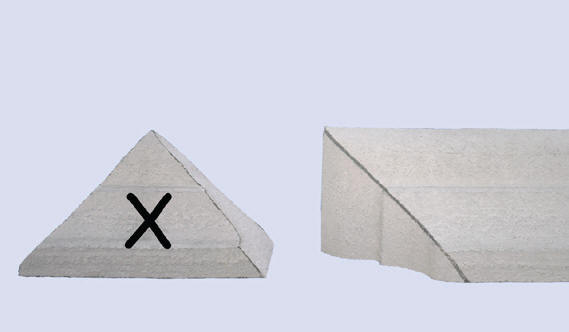

becomes the return. Flip end piece

which, will be used as the

return. Repeat procedure for return on

other side of sill.

|

Slide the end piece

over to the wedge cut in the sill and

assemble using glue, such as 100% clear

silicone. Repeat on the opposite

side of the sill. Create both

returns on the sill first before gluing

sill to the wall. You may even use

toothpicks or nails to hold the end

pieces to the sill while the glue dries.

Seams must be "StyroCaulk" filled.

|

Optional Pre-finished Ends

StyroTrim window sills may also be ordered with finished ends so the

above procedure will be unnecessary. Order your sills with finished ends

by giving us the sill length (in inches) you need.

Arches

StyroTrim window and door arches may also be ordered in every style of

trim available. Your arch size and shape is as simple as giving us the inside

width and the inside height measurements. Circles can be made by using 2 arches

of equal size.

Installation

Here are some basic tools and materials needed to install your new StyroTrim accents:

- Standard (disposable) wood saw or power saw with masonry blade.

- S-curved bead of clear 100 percent silicone (glue)

- Caulking

- Paint or color coating

Your StyroTrim treatments will arrive in 85-inch strip lengths. Follow these steps to cut, glue, caulk, and install your treatments:

Step 1: Using a standard (disposable) wood saw or power saw

with a masonry blade, cut through

the outer exterior finish and foam core of your trim to the desired lengths (for a miter,

cut the corners diagonally just as you would any other trim, like wood).

Step 2: Glue your treatments to the wall, window or door

using a low solvent exterior construction adhesive. We recommend a

generous S-curved bead of clear 100 percent silicone. Examples of suitable

adhesives are: GE Silicone II 100% Silicone Household Glue, Liquid Nails

Construction Adhesive, or Loctite PL 300 VOC Foamboard Adhesive. Apply the

glue or silicone liberally on the inside of the treatments but avoid the

surface you wish to paint. Firmly place

the treatment against the structure and hold for several seconds.

TIP: Double-sided foam tape holds the treatment against

the structure to allow the adhesive to cure. You may also temporarily

use strips of masking tape across the outside surface of the

trim to hold in place until the adhesive cures. On heavier installations, a nail or screw can

be driven into the wall first (then cut the heads off) and used to pin the accent to keep

it in place while the adhesive cures.

Step 3: Once the adhesive dries and the treatments are

secure against the structure, fill any seams or gaps with stucco patch

or our exclusive StyroCaulk caulking.

Step 4: Treatments are now ready for painting or color

coating with the

color or finish of your choice.

"I was very skeptical as to how easy it would

be, but the whole job took much less time than I

had anticipated. The installation instructions are easy to follow, even for a

non-handyperson like myself".

Wendy DeMico, Syracuse, NY.

|

Coast to Coast Delivery

Coast to Coast Delivery

Coast to Coast Delivery

Coast to Coast Delivery